An American jeans horror story, starting Covid-19 & Dynamic Denim

By Maurice Malone Published January 17, 2022

We made it through the worst days of an ongoing pandemic and 6-months of incompetence from a horrible sewing contractor. At last, our ready-to-ship stocked American-made jeans are back!

New styles (the first production since the pandemic began) that have been sewn in Los Angeles and will be on their way to our New York studio by the end of the day.

We manufactured two Grand Street 14-oz. raw denim jeans. The first style originally went on sale way back in August 2021. It is produced in a rare blue tone, made in USA Cone White Oak redline selvedge. In November, as a contrasting option, we added to the website, 57 units of a dark indigo shade of Japanese selvedge.

Making jeans in the USA is not easy. You'd either have to love doing it or be a fool not to make production overseas, saving money and aggravation. We're fools in love!

Making American-made jeans is not as easy as producing jeans overseas. Many think it is the higher cost that drives brands to produce outside the borders, however, the cost is not the only issue. Naturally, most would assume language and location makes things easier. It doesn't.

A lot more work and coordination with multiple suppliers and contractors is involved when working with jean manufacturers in the USA. As a brand, you have to supply all or most of the parts that go into the product. The main contractor is usually in charge of the sewing. Larger operations may cut in-house, other sewers require coordination with a separate cutting contractor. The same thing goes for embroideries and prints. Any parts that require prints or embroideries must be sorted after cutting and taken to the contractor conducting that portion of the production. Fabrics, labels, buttons, tags, etc. all have to be delivered to the factory. The patterns used to cut, called markers, have to be produced to match the width of the fabric and delivered to the cutter.

If a brand is dealing with jeans that are washed, there is another complicated process that starts with testing the fabric for the after-effects of washing. The industrial laundry that washes jeans is most often another factory contactor. It requires working through multiple sampling rounds and fittings to find the shrinkage rate of the fabric. After confirming both vertical and horizontal shrinkage rates, the numbers are given to the pattern maker to be added or deducted into the style's pattern specs. This changes for every fabric used in a style.

Juxtapose this to making tech packs, which are blueprint documents for making garments, and emailing them to an overseas factory. Later, simply answer emailed questions, or over video conference and wait for samples to be approved or send back correction comments.

Through Covid-19 and Dynamic Denim blunders, American-made stock jeans are back!

The story of this production started way back in early June 2021 after giving a 50% deposit to the Los Angeles-based Dynamic Denim, which has an office address at an actual jeans factory. We were later informed, we fell victim to a broker with a website, masquerading as a denim factory.

In the spring of 2021, as the U.S. began to re-open for business and people started going outside again, our online alterations business exploded. The work overload slowed our custom-made jeans production, causing us to stop taking orders for about a month. We had a decision to make. Should we use our good spring seasons sales to hire more help or produce stocked jeans again?

We felt there was pinned-up demand for our jeans. Deciding it was a good time to resume mass production, and put some stock back on our bare shelves.

However, the factory we worked with for most of our years of U.S. production was no longer in business. We had to first find a new factory. Online searching led us to the Dynamic Denim website, which is run by proclaimed owner and site builder Martin Barrack. Because of Covid concerns, we decided to do a video walk-through instead of traveling to LA for a personal meeting and walkthrough of the manufacturing facilities. We would pay dearly for this error in judgment.

Martin proved to be a bungling go-between who deceived us and mistranslated our detailed instructions to those he contracted to do our work. Originally quoting 4 to 6 weeks to make our order, Martin failed to produce the first set of two pre-production approval samples (sizes 32 & 44) required to check for errors before production could begin until the last week of September. Weeks and sometimes months were wasted as we found we had to resend the same information multiple times.

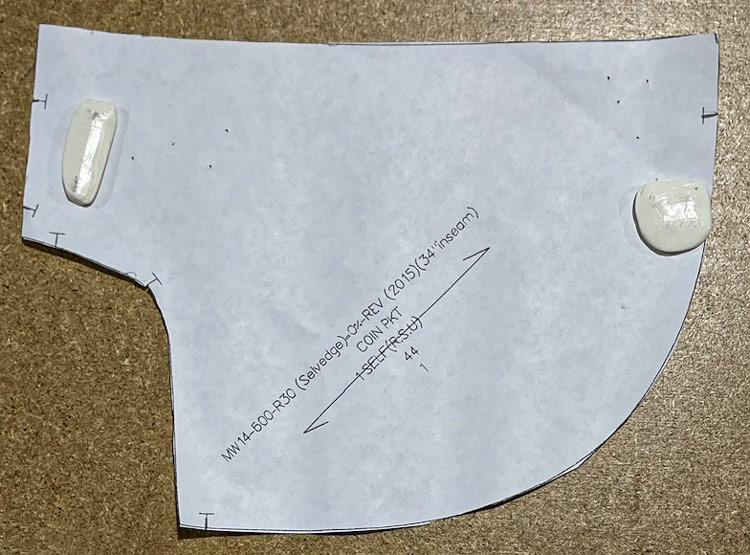

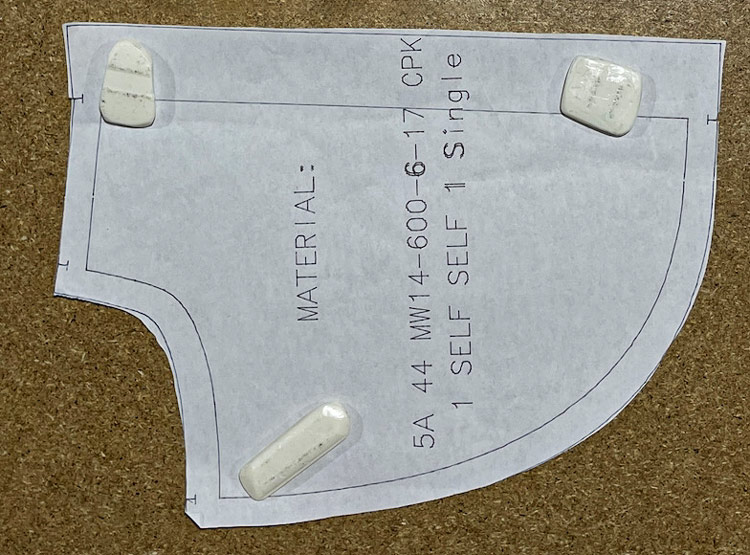

To make a long story short, they tried to remake our patterns and failed. We warned them from the start, "do not remake our patterns!" We asked Martin to use our digital pattern files, and make three simple tweaks. 4-months later, after multiple denials of remaking our patterns, and submitting badly fitting jeans, they sent us paper copies of the patterns they were using. They were not our patterns.

Our coin pocket pattern

Coin pocket pattern from Dynamic Denim

Don Lee, the factory's production manager, and now the second person Martin assigned to coordinate us agreed that we should send them our original markers (patterns for cutting), so production could finally begin. Pissed, because we could have done this back in June if I could have foreseen the incompetence that would follow, but also relieved because we would finally get going. We were hopeful we would not miss our highly anticipated Holiday sales.

About 5-months after placing the production order, delivery was finally confirmed to be December 16. About 10-days after I delivered the markers for cutting to begin, I followed up with Don to make sure things were on track. No reply. Days of calls and emails later, I finally get Martin on the phone. "Didn't you get my message, Don doesn't want to do the production, we gave up on it," he said. I could only laugh in disbelief.

"Yea, I sent you a text message about a week ago," Martin said. I quickly checked my phone, even though I knew nothing was there.

"I have no messages from you or Don," and texted him a screenshot of our last messages from October. "I also checked my emails. Nothing," I said.

Frustrated, I asked a friend who lives in LA and owns the Blueprint Apparel Group in El Monte, California, to go by to see what was going on. After his investigation, he advised me, Martin was not the factory owner, but a broker. However, he did know the real factory owner. From his years of experience doing business in the L.A. denim industry, he summarized the situation

"It comes down to them not making money on your order. When you originally placed the order, business for them was slow and they underpriced it to secure the order. Now that things are better, and costs have risen, they see there's not much profit, so they don't want to do it," he said.

I asked my friend to meet with them about finishing my production or sending my money back right away so I could quickly find a new factory and not miss shipping my customers' orders before Christmas. They delayed. About a week later we received a forwarded Dynamic Denim invoice, which I predicted would come with made-up and overpriced charges to avoid giving our money back. Anticipating they would hand over the fabric they said was purchased for our order, their invoice stated we owed $108.

They billed us for 600 yards of fabric. However, we received less than 500 yards of extremely flawed denim. We had to find the same fabric to complete the required yards to fill our cut. We ended up buying it at about 20% less per yard than what Martin told us the fabric cost.

After some scrambling, my friend did find us a new sewing contractor and managed all the aspects of the production through his company Blueprint Apparel. We plan to run future productions through his company, learning from my experience of working over 25-years doing production in the Los Angeles area, if you are not working with a trusted factory, you have to be there or have someone working for you there. If not, your production will often get pushed aside and delayed for some other brand that does have someone visiting in the factory.

We're happy to announce after 7-months, the jeans are finally completed and will be shipping the day after they reach our office. Thank you to all those who showed patience and support for our products. I feel like, next I owe a behind-the-scenes article about the struggles and time it takes to make custom jeans and shirts.