Why Gustin Denim Fans Like To Choose Us for Chain Stitch Hemming

By Maurice Malone Published January 18, 2026

People who buy Gustin jeans tend to pay close attention to construction details. Fabric weight, stitching style, and manufacturing choices matter to them, and that same attention carries over once the jeans arrive. For most Gustin buyers, hemming is unavoidable, since Gustin typically ships jeans with long inseams. The decision isn’t whether to hem them, but how.

For these customers, hemming isn’t about keeping an original hem intact. It’s about resewing the hem the way the jeans were originally made—using the same type of chain stitch, the same thread approach, and the same supporting details used at the factory. That distinction is central to why many Gustin buyers end up choosing Williamsburg Garment Company for chain-stitch hemming.

Understanding How Gustin Jeans Are Originally Hemmed

Gustin jeans are sewn with chain-stitched hems, a construction method commonly associated with heritage denim. On many Gustin indigo styles, there is also a specific factory detail that often gets overlooked: a red bar tack placed at the inseam, paired with a red chain stitch visible on the inside of the hem.

This detail isn’t decorative. The bar tack reinforces the chain stitch at the inseam, helping prevent unraveling, while the red thread serves as a recognizable construction marker. When those elements are missing, misplaced, or sewn incorrectly, the hem no longer reflects how the jeans were originally made.

Years ago, as we began hemming increasing numbers of Gustin jeans, it became clear that offering chain stitching alone wasn’t enough. To properly replicate the factory finish, the inseam bar tack had to be part of the process. As far as we know, we were among the first shops to offer bar tacking as an option alongside chain-stitch hemming, particularly through an online ordering system. We didn’t add it as a novelty—it was simply how the jeans were built to begin with.

That approach resonated with Gustin buyers who were paying attention to the details, and over time, many of them found their way to us through comparison, discussion, and word of mouth.

When Careful Customers Ask Detailed Questions

That level of scrutiny showed up clearly with a recent customer who contacted us before sending in his jeans. He called to ask whether we chain stitch hems, then followed up with a long series of emails. He wanted to know about bar tacks, thread choices, and whether we had real experience working on Gustin jeans.

At first, the questions seemed excessive. Once his jeans arrived, the reason became obvious.

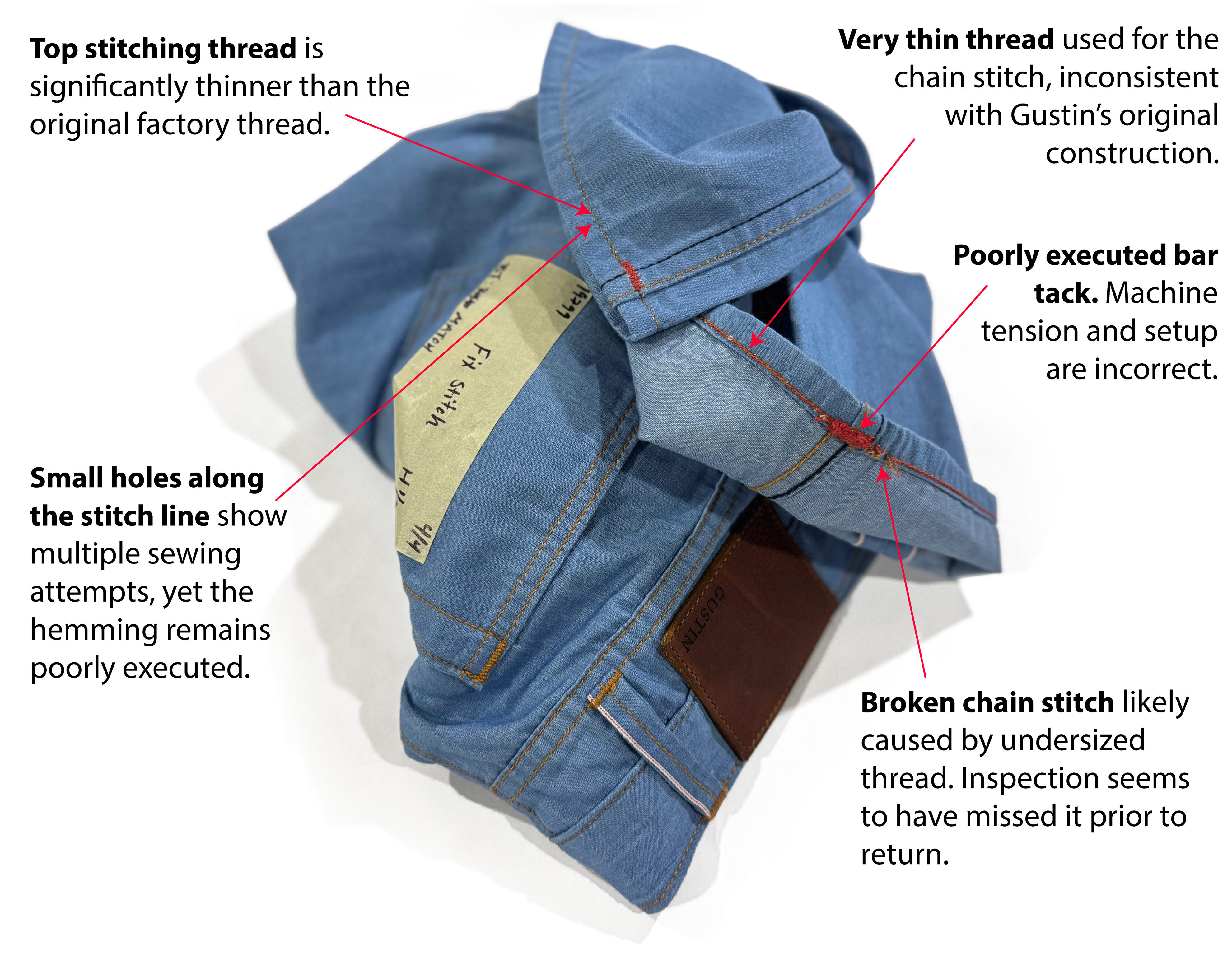

They had already been hemmed elsewhere, and the work didn’t align with Gustin’s original construction. The chain stitch was sewn with thin thread. The bar tacks were poorly executed. The overall finish suggested that the tailor understood what they were trying to replicate, but not how to do it correctly.

Redoing hems from another tailor isn’t unusual for us. What stood out here was that the jeans had already been chain stitched and bar tacked by another denim tailoring service—something we hadn’t seen often before.

When I asked where the work had been done, the customer told me it was the hemming service recommended directly on Gustin’s website. That explained his hesitation. If the suggested option couldn’t reproduce the factory details accurately, he wanted to be certain the next shop could.

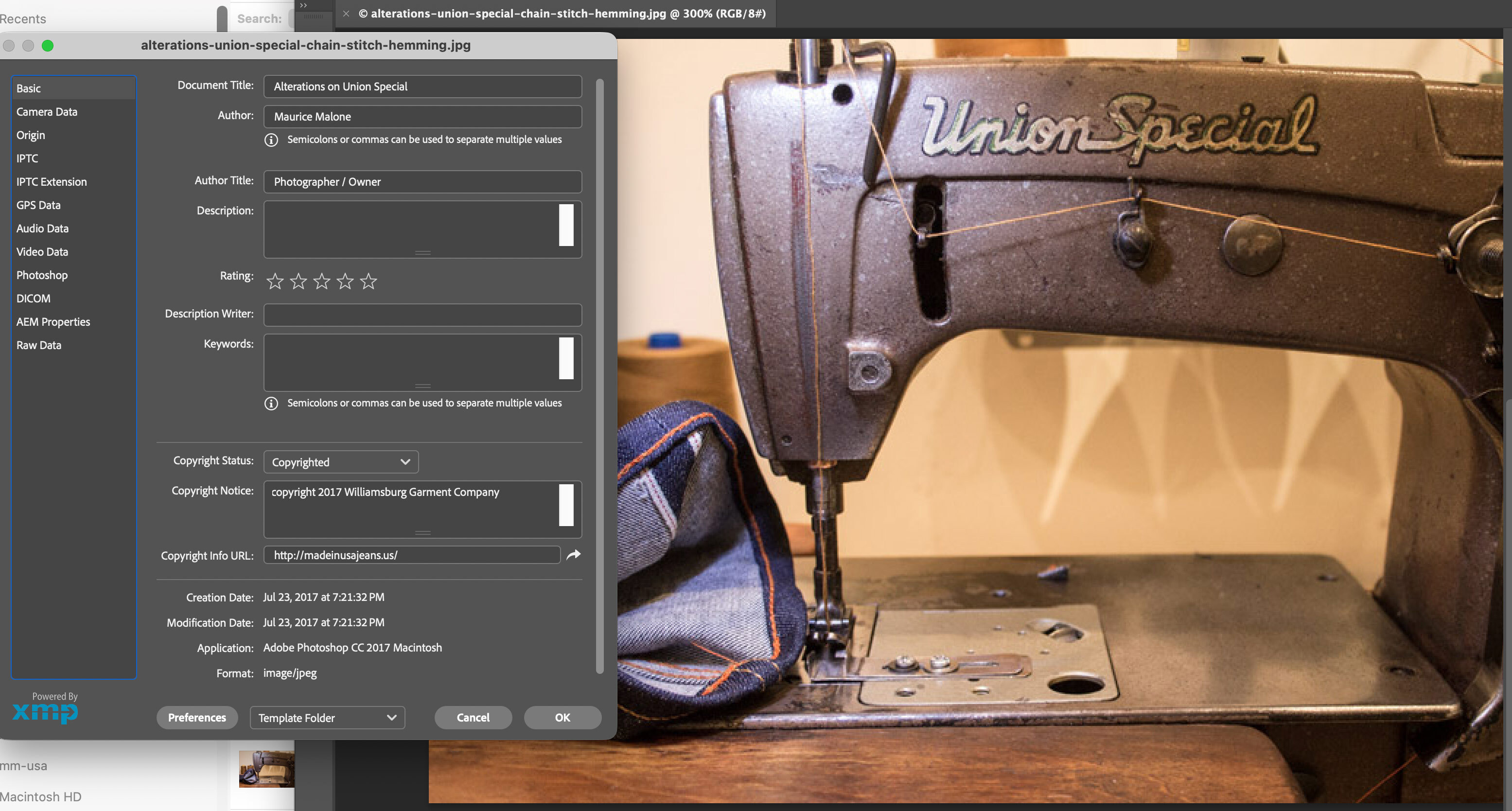

Discovering Our Photo on Gustin’s Website

Out of curiosity, I visited Gustin’s website to see how they were presenting their hemming recommendations. That’s when something unexpected stood out. The image used to represent the recommended chain-stitch hemming service was one of ours—a photograph taken in 2017 inside Williamsburg Garment Company, showing our Union Special machine and our own jeans with clean chain stitching.

The irony was hard to miss. The photo showed exactly the kind of factory-style construction Gustin buyers are looking for, yet it was being used to market a competing denim service as Gustin’s suggested option. It also explained why customers responded so strongly to the image, even when the results they received elsewhere didn’t match what they had seen.

Correcting the Work and Showing the Difference

What ultimately matters is how the work looks and functions once it has been corrected. The difference between a hem that simply measures the right length and one that is sewn correctly becomes clear as soon as the jeans are back on the table. Stitch quality, thread size, bar tack placement, and consistency either align with the original factory construction, or they don’t.

After removing the failed hemming and bar tacking, we resewed the jeans using proper thread sizes and a correctly set chain-stitch machine. The inseam bar tack was placed intentionally, matching Gustin’s original construction. Once finished, the hems no longer showed signs of trial-and-error sewing—they simply looked right.

We applied the same process to a second pair of Gustin jeans from the same customer, this time in red-weft denim. The before-and-after difference was clear. The corrected hems matched the factory intent, both visually and structurally.

Before: Correcting Bad Hemming

After: Correcting Bad Hemming

Why Gustin Buyers Keep Choosing Us

This isn’t about exclusivity or claiming that only one shop can hem Gustin jeans. It’s about understanding the goal. Gustin buyers aren’t trying to preserve an original hem. They want the hem resewn the way the jeans were made in the first place, using the right machines, the right stitch, and the right supporting details—especially the inseam bar tack that Gustin uses as both a functional and visual marker.

That’s why so many Gustin customers continue to choose us. We didn’t just offer chain stitching early on. We paid attention to how the jeans were actually built and structured our hemming options around that reality. Thread choice matters. Bar tack placement matters. Execution matters.

When the customer’s jeans were finished, everything finally lined up. The hems looked right. The bar tacks were correct. The sewing matched the factory intent instead of fighting it. More importantly, the customer understood that his instinct to ask questions wasn’t overkill—it was necessary.

For Gustin buyers especially, that consistency is the difference, and it’s why so many of them continue to choose us for chain-stitch hemming.