American Made Jeans – You'd Have To Love Them!

By Laura Santos, Rasheed Bailey & Maurice Malone Published February 15, 2022

Ever wonder why the number of brands making American-made jeans keeps dwindling? Is it solely the lower cost driving labels overseas, or is it more to it?

"As I said before and will say again, making jeans in the USA is difficult in comparison to producing in other countries," says Williamsburg owner/designer Maurice Malone. "You have to love the craft, and not mind working harder for lower returns."

Although it is difficult the results are worth it. We were knocked down in 2020 and it took us nearly 2-years to get off the mat. Without getting deep into the weeds, for a better understanding of some of the steps and issues in what we do, see our previous article "An American Jeans Horror Story."

Producing our first in-stock jeans since the beginning of the pandemic took an unbelievable 6-months. We were excited to start with an all-American production using rare made in the USA Cone White Oak denim, with sewing in Los Angeles. We began our come-back with a new factory in June 2021, and found disappointment with delays and incompetence, having to switch factories in late November.

As we re-organized things with the new factory, we decided to add a second style option to make up for the lost time. To do this seamlessly we utilized the same patterns and thread colors, inserting a second fabric that could compliment the original production's denim. The new fabric had to be of equal width to cut together with the existing textile, and different enough to register as a new style.

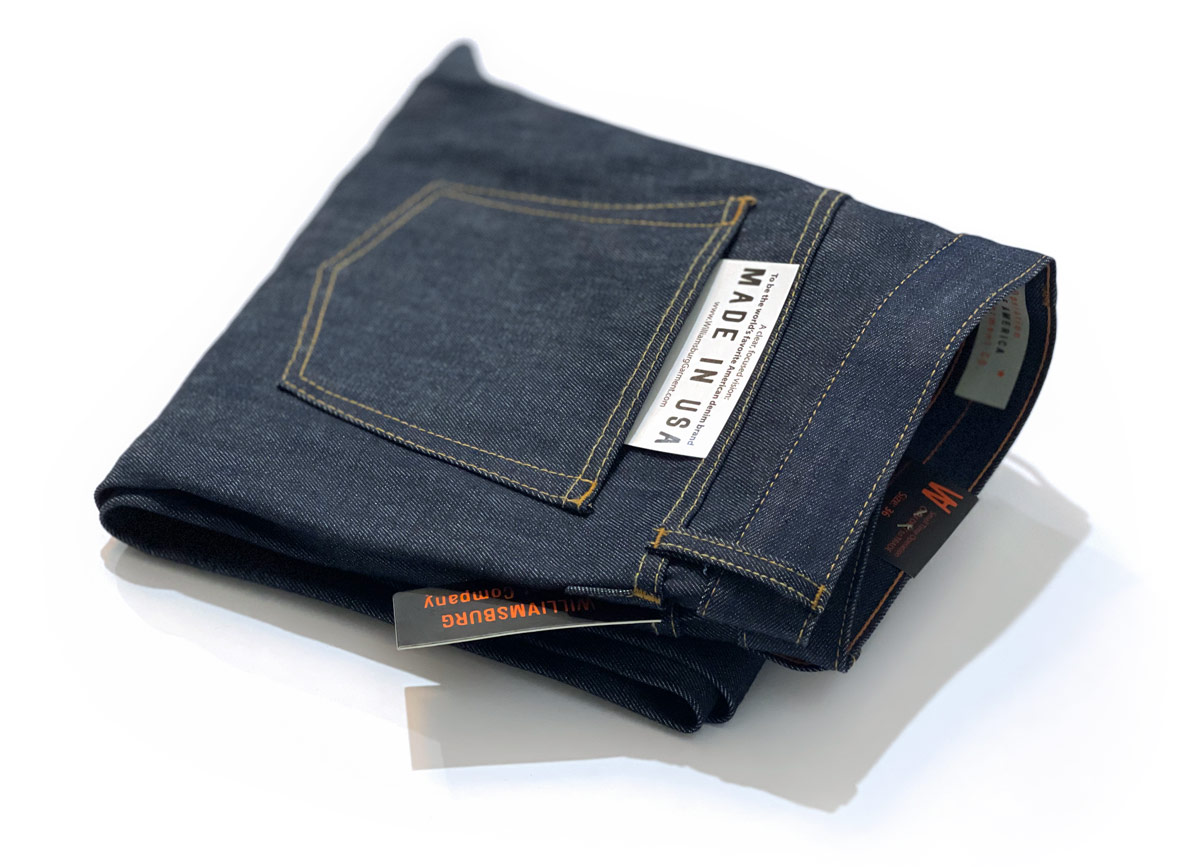

We completed two choices of our best-selling Grand Street slim fit. At first glance, they may seem nearly identical but they have their differences. First starting with fabric, which is the foundation of every pair of jeans. The initial production utilizes American-made denim from the now-closed Cone White Oak Mills in North Carolina. 14-oz. in weight, the color is bluer in shade than our second style, which was woven in Japan. Likewise, a 14-oz. selvedge raw denim, but has a deep indigo dark shade.

To complement each tone of denim, we inserted contrasting rivet color combos into the mix. The rivet's copper washers and black nails embolden the bluer Cone Denim. In divergence, we reverse them to black washers and copper nails, lowering the contrast and darkening the mood of the Japanese denim. With both styles made in limited volumes (only 57 in the Japanese selvedge), and the first after the company survived the pandemic, we believe the two will be highly desired by denim collectors.