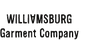

In the production of our men's jeans, the 6-thread serger (also known as the overlock) is used only at the outseam curve of the hips. The machine is needed here because the outseams of selvedge jeans are straight, up to the point where the hips curve into the waist.

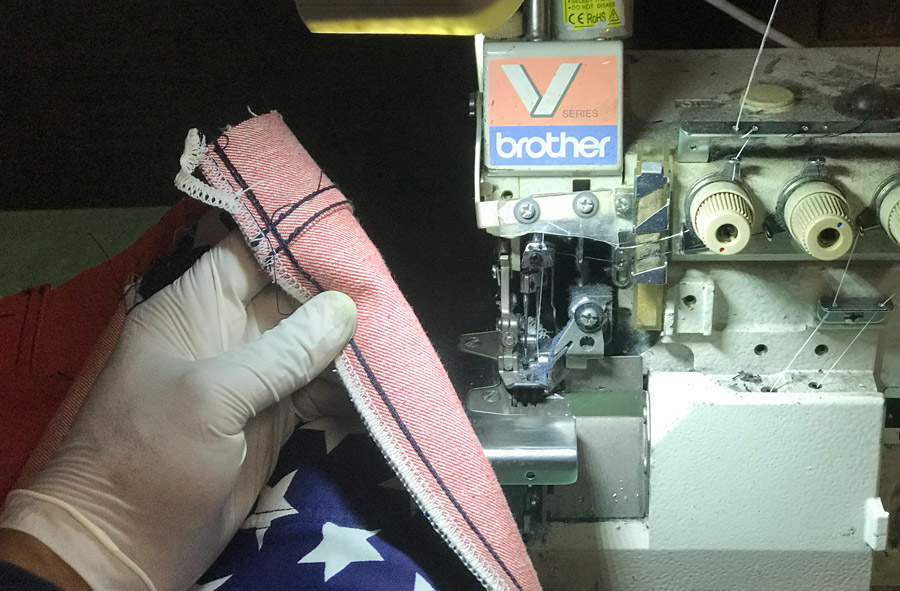

In the production of custom made jeans, we first close the outseams with a chain stitch. After, we go over the hip area with the 6-thread serger, which trims the raw edges evenly, while adding an overlock stitch.

Some makers use the machine at the inseam with a single-needle topstitch. We mainly use that construction with our women's jeans. However, when working with denim weighing 18 ounces or more, an overlocked inseam with single-needle topstitching is common. This is because sewing multiple layers of extra-heavy denim is difficult to manage with lap seam sewing.

Bargain and mid-market level makers will sometimes close the outseam with the 6-thread serger. This is to save time and avoid the extra step of overlocking each outseam panel on non-selvedge fabric, then sewing them together with either a single needle lock-stitch or chain stitch, before finally pressing the sewn panels open, creating a busted (butterfly) seam.

Words & images: Maurice Malone April 6, 2020