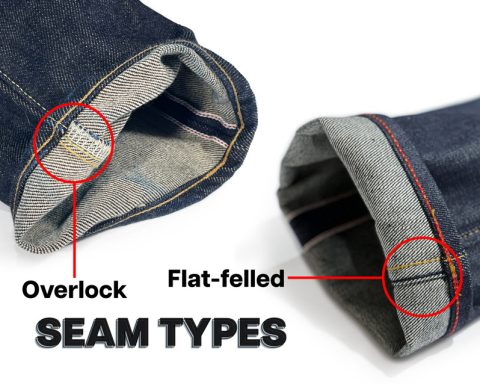

You love work pants but wish they came with a modern fit for casual wear. Here we explain the step-by-step process that went into tapering a pair of triple-needle flat-felled chain-stitched inseam Carhartt carpenter pants from a 20-inch wide leg, down to a 15-inch opening.

It’s a job that not many tailors or alterations services do because of the skill and equipment needed. As a denim factory with all the heavy-duty machinery required to deal with triple-needle stitching at both the out-seam and inseam of work pants, one can argue our added enhancements look better than the original manufacturing.

The tapering process

Step – 1: Inseam length

In the above before & after photo, you can note the lines drawn above the hem of the pants. It marks the requested inseam length. 1-inch is added to account for the two 1/2-inch folds of the hem.

From the start, we cut the inseam to match the customer’s requested inseam length. However, the inseam always grows during the sewing process when we put the inseam back together. The fabric stretches while being pulled through the flat-felled sewing machine. Pressing at the end of sewing also causes the fabric fibers to flatten and grow. We leave the length as-is, which is usually longer, anticipating the pants to relax back into place after wash and wear.

Step – 2: Undo the inseam

The requested inseam for this pant was 28-inches. After cutting the pants down to the new length, plus 1-inch, we pull the chain stitching apart at the inseam. This is a fairly quick process. For factories, the chain stitch is the strongest, and most effortless to pull apart in cases when re-sewing is needed.

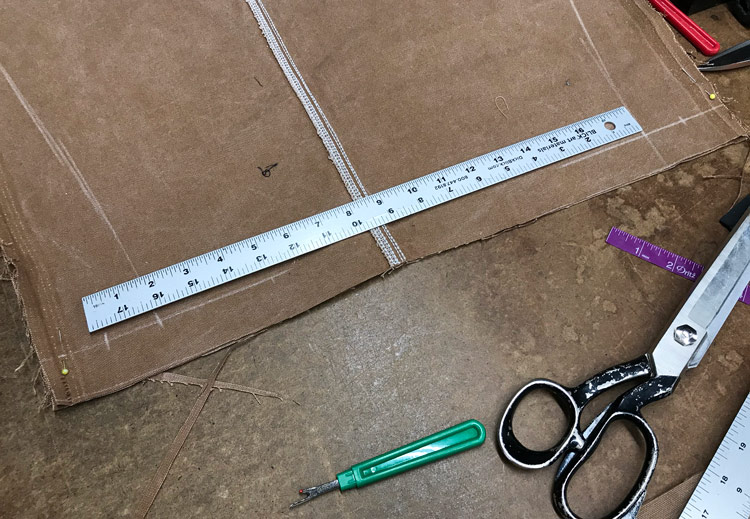

Step – 3: Re-Draft leg shape

The pants are opened and placed on the table to re-draft the leg shape. The leg of this Carhartt carpenter initially measured 20-inches in total circumference. The customer requested to bring it down to 15-inches.

Below, note the leg opening measurement is 16 1/8 inches. 1 1/8-inches is added for seam allowance. In the photo above, markings for the knee can be seen. It highlights the area where we make the turn towards the crotch.

Step – 4: Sewing

Finally, using the three-needle flat-felled sewing machine, the inseam is closed, and the hem is chain-stitched with a Union Special sewing machine. Last, the garment is pressed and packed for shipping back to the customer.

Under our alterations services menu, we offer triple-needle tapering, Double-needle, and single-needle tapering services. We charge slightly more for triple-needle work because of the machine set-up and change-over.